Our Quality Assurance Process

Quality control at Cypress Technologies covers every production phase, from initial design to delivery. Our dedicated Quality Assurance Team ensures that products meet all specifications and perform as required.

Every assembly undergoes thorough testing before it is released. Our testing procedures include:

Comprehensive Testing,

Validation, and Inspection

We verify product quality at every stage of the manufacturing process using a comprehensive suite of tests and inspections to ensure reliability and performance.

This robust testing process minimizes the risk of defects, enhances performance, and guarantees that products deliver reliable results in real-world applications.

Design and Development: We collaborate with clients to ensure designs meet both functional and quality requirements, preventing potential issues before production begins.

Manufacturing: Our teams oversee production to maintain consistency and accuracy, ensuring all components are assembled and produced to exact specifications.

Functional Testing: We validate that each product operates as intended, meeting all performance and reliability standards.

Enclosure Testing: Enclosures are tested at the PCB, harness, and final assembly levels to ensure proper fit, protection, and functionality.

Cable/Harness Insulation Testing: Electrical insulation integrity is evaluated to confirm safe and reliable operation.

High-Voltage AC/DC Testing: High-voltage tests ensure components can handle electrical stresses without compromising safety or performance.

Environmental Testing: Products are subjected to simulated environmental conditions such as temperature, humidity, and vibration to verify durability and reliability.

Part/PCB Programming: We program and verify the functionality of parts and PCBs to ensure seamless operation.

Data Integrity Testing: Rigorous data checks ensure accurate and reliable performance under all conditions.

In-House Designed Custom Test Fixtures: We develop custom test fixtures to accommodate unique product specifications and ensure precision testing.

Sealant Testing (Low Pressure): Sealants are tested to confirm they provide proper protection against contaminants without compromising component integrity.

Vacuum Testing: Vacuum systems are inspected to ensure proper operation and sealing capabilities.

Battery/Load Testing: Battery and load capacities are evaluated to confirm they meet operational requirements under various conditions.

Burn-In Testing: Products undergo extended testing with and without power to identify potential failures and ensure long-term reliability.

Delivery: Final inspections confirm each product meets specifications before it ships, ensuring quality and reliability for end-users.

Continuous Improvement

We regularly review and update our quality systems to keep them efficient and effective. Our commitment to continuous improvement means we actively look for ways to enhance quality and streamline processes. Regular audits and change controls help ensure we are optimizing our operations.

Measurable outcomes back our dedication to improvement:

2024 Total First Pass Yield:

We achieved an impressive 96.09%, exceeding our goal of >95%.

Team Collaboration

and Idea Sharing

We believe innovation comes from within. Cypress Technologies has developed an internal system encouraging employees to submit process and quality improvement ideas. These ideas are reviewed and discussed during our regular town hall meetings, where team members collaborate to identify the most impactful suggestions. Implementing these ideas helps us stay agile, improve efficiency, and maintain our commitment to excellence.

Employee Submittal of Continuous Improvements: With a 2024 goal of ≥4 submissions per month, our team more than doubled expectations, averaging 8 ideas per month.

By empowering our team and continuously refining our processes, Cypress Technologies ensures we remain a trusted partner in electronic contract manufacturing

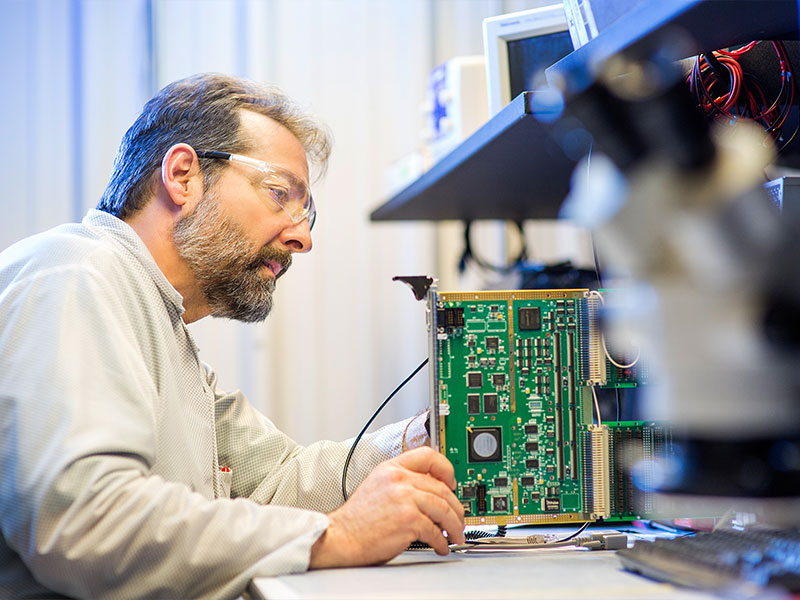

Skilled Quality Professionals

They conduct inspections, verify measurements, and evaluate workmanship throughout production. Their attention to detail ensures that every product meets our high standards.

Detailed Reporting and Communication

We prioritize clear communication with our clients. Our team provides detailed reports on production progress, inspection results, and any necessary adjustments. Keeping clients informed throughout the process helps ensure that final products meet their expectations.

Ensuring Product Reliability at Every Stage

We verify product quality at every stage of the manufacturing process:

- Design and Development: We collaborate with clients to ensure designs meet both functional and quality requirements.

- Manufacturing: Our teams oversee production to maintain consistency and accuracy.

- Delivery: Final inspections ensure that each product meets specifications before it ships.

This comprehensive approach helps minimize the risk of defects and ensures that products perform reliably in the field.

Why Quality Matters

Quality is central to the success of any manufacturing project. Reliable products help reduce downtime, improve customer satisfaction, and decrease the risk of costly failures. At Cypress Technologies, our focus on quality gives our clients confidence that they receive reliable products.

Partner with Cypress Technologies for Dependable Quality

Choosing Cypress Technologies means partnering with a manufacturer who prioritizes quality in every step of the process.

Our ISO 9001:2015 QMS certification and hands-on quality assurance ensure that the products we deliver meet the highest performance and reliability standards.

Cypress Technologies will deliver high quality products and services that exceed our customers’ expectations through integrity, agility, innovation, and continuous improvement.

Contact us today to learn how our quality assurance process can support your business needs.