Electronic contract manufacturing is a specialized field of manufacturing for PCB design and assembly, complete electronic assemblies, electronic component sourcing and procurement, system integration, and electronic product quality testing. They play a vital role in many different industries today, with the exponential growth of integrated electronics in systems across the board.

The right electronic CM has much to offer your project, from faster time-to-market to improved quality assurance, and even the ability to scale production up or down, accommodating fluctuations in market demand. When you’re looking for a new CM for your electronics products or components, here are a few things to keep in mind.

Most electronic manufacturers are experienced in a set group of industries or applications, specializing in particular components or services. Make sure to match your product’s needs to the manufacturer’s specialization and examine their expertise as well. They should know the quality standards your product will need to meet and have the certifications and manufacturing capabilities to make that product.

A good electronic contract manufacturer can also use their expertise to offer design assistance at the very least, finding ways to improve your product’s performance and the project’s overall costs. They’ll have a good understanding not just of the ways a design can improve manufacturability, but also the supply chain needed to build the product.

Another important factor to consider is how long the company has been in business and how much experience they have in the industry. A company that has been around for several decades has proven its staying power, being able to navigate economic fluctuations and supply chain disruptions. A long-standing company also is more likely to have a more experienced and well-rounded workforce to offer, and more insight into their industry specializations.

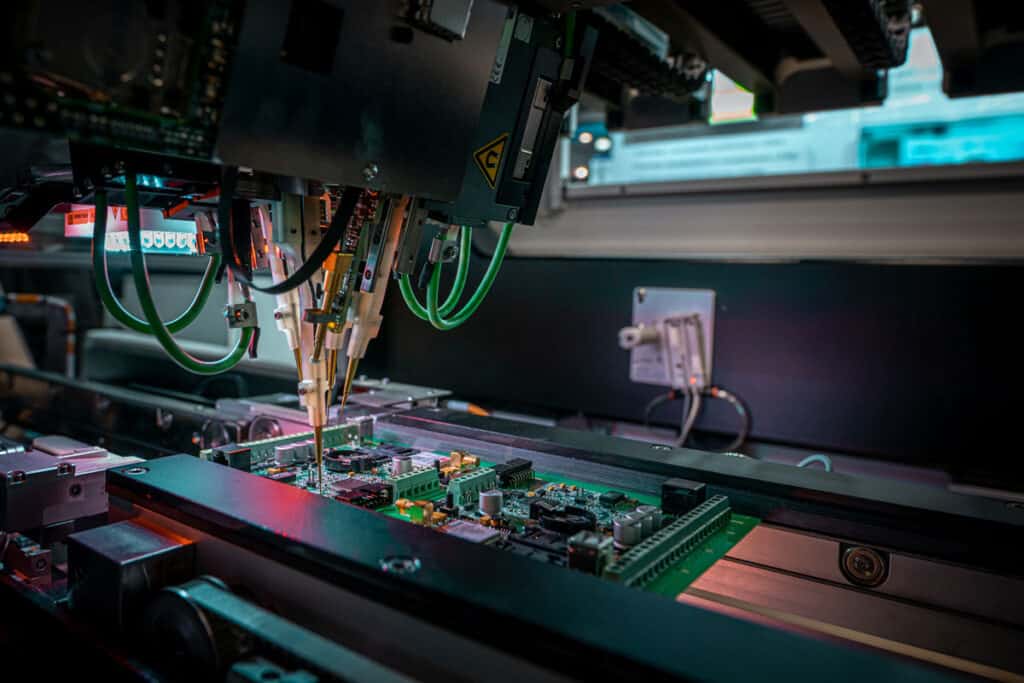

Another key thing to consider when you’re looking into electronic contract manufacturing is the capabilities of the company. They should have a well-maintained and well-equipped facility with the technology necessary to meet your standards of quality, as well as the ability to scale production up or down as needs require.

A good partner should also collaborate with your team and communicate with transparency throughout the manufacturing process. They should be willing to work with you to find the best possible design and be responsive to your feedback and your standards as well. A good way to examine a company’s capabilities and collaboration is to see if they have any testimonies from previous or current customers–the company’s history is often found on their website or other resources–or contact others that have worked with them in the past and see what that company’s reputation is like.

Cypress Technologies has been a leader in electronic contract manufacturing since 1987, with a history of integrity, long-term relationships, and superior manufacturing. Check out our website to learn more about how we can serve you.

Our People First Company Culture Fuels Success When you walk into Cypress Technologies, you will…

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

This website uses cookies.