Custom Manufacturing & Assembly Excellence

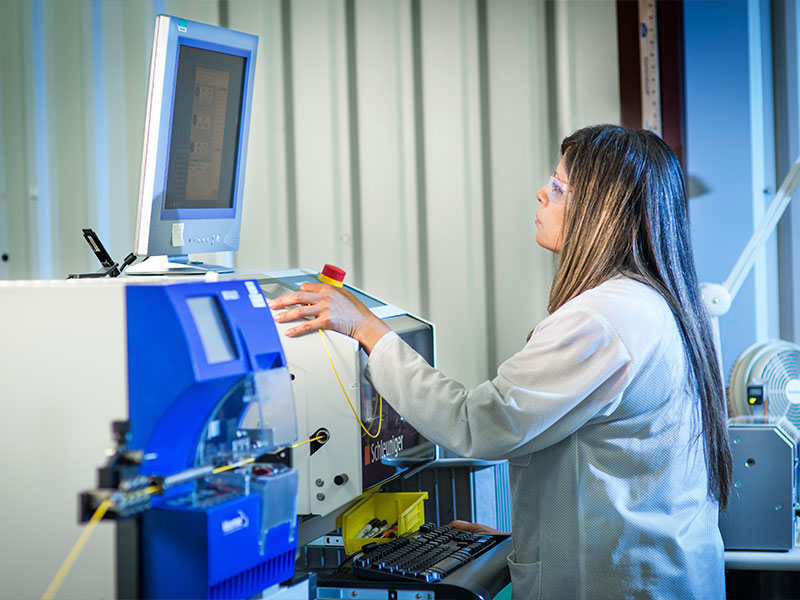

Precision, reliability, and efficiency are critical in electronics manufacturing and assembly, and Cypress Technologies is built to deliver. Our highly qualified team members are experts at creating high-value assemblies. Every project benefits from thorough testing and precise manufacturing techniques from prototype development to full-scale production.

We take a customized approach to every project, ensuring that we meet the highest standards of quality and performance. With a deep commitment to excellence, we tailor our solutions to address your unique needs, delivering flawless results in the field—every time.

Comprehensive Electronics

Manufacturing & Assembly Services

Our electronics manufacturing and assembly capabilities cover a wide range of industries and applications, with a focus on delivering highly reliable, performance-driven solutions. We integrate advanced lean manufacturing principles to optimize processes, reduce waste, and improve turnaround times.

Our Manufacturing & Assembly Capabilities Include:

Box & Panel

Assembly

Custom-built enclosures, integrated electronics, and wiring solutions for robust performance.

PCB Assembly

& Ruggedization

Surface mount and through-hole PCB assembly with enhanced durability for demanding applications.

Electromechanical

Assembly

Precision integration of electrical and mechanical components into fully functional assemblies.

Cable & Harness

Assembly

High-quality custom cable and wire harness solutions tailored to specific applications.

Testing & Quality

Assurance

Advanced testing methodologies, including functional testing, test fixture design, and environmental screening.

Custom

Machining

In-house machining for metals and plastics to support complex designs and prototyping.

Failure Analysis

& Repair

Troubleshooting and diagnostics to identify issues and optimize product reliability.

We ensure that every product undergoes rigorous inspection and testing before it leaves our facility, reducing failure rates and delivering long-term performance you can trust.

Full Program

Documentation

Complete traceability and data integrity for compliance and quality assurance.

We ensure that every product undergoes rigorous inspection and testing before it leaves our facility, reducing failure rates and delivering long-term performance you can trust.

Lean Manufacturing for Greater Efficiency & Cost Savings

At Cypress Technologies, lean manufacturing is more than a process—it’s our core philosophy. Our commitment to continuous improvement and efficiency allows us to:

- Reduce production costs while maintaining quality.

- Minimize waste and optimize resource utilization.

- Adapt quickly to market demands and design changes.

- Shorten lead times and improve delivery schedules.

We anticipate changes before they happen, using revision control, bill of materials (BOM) tracking, and real-time process monitoring to ensure a seamless production flow. Our team continually seeks ways to refine and enhance our manufacturing processes, ensuring you stay ahead of the competition.

Why Choose Cypress Technologies for Electronics Manufacturing & Assembly?

With over 37 years of experience in the industry, Cypress Technologies has developed a strong reputation for delivering electronics manufacturing and assembly solutions that prioritize quality, efficiency, and adaptability.

What We Deliver:

Tailored Solutions

for Complex Assemblies

We specialize in manufacturing assemblies that require extensive testing and precision production. Whether your products are built for harsh environments, high-performance applications, or require strict regulatory compliance, our team has the expertise to deliver.

Scalable Production

to Fit Your Needs

Our facility and team can scale operations based on your requirements, from small-batch prototypes to full-scale production. Our lean manufacturing approach ensures we can quickly adapt to changing production demands while maintaining efficiency and cost-effectiveness.

Procurement & Supply

Chain Excellence

Cypress Technologies utilizes an elite procurement system that manages pricing and availability across more than 1,500 global vendors. This system, combined with our MRP and Just-in-Time (JIT) manufacturing strategies, optimizes inventory management and ensures materials are available only when needed—reducing waste and improving cost efficiency.

Comprehensive Quality

Assurance & Testing

We manufacture and assemble reliable, durable products. Every assembly undergoes extensive testing and validation, including functional testing, environmental screening, high-voltage testing, and test fixture design. Our quality control processes are designed to catch and correct potential defects before they reach the field, saving our customers time and costs.

Partner with Cypress Technologies for Top-Notch Manufacturing & Assembly

When you partner with Cypress Technologies, you’re working with a team that brings 200+ years of combined experience in electronics manufacturing and assembly.

We commit to delivering the highest level of quality, efficiency, and precision every step of the way.

Contact us today to discuss your project and discover how our expertise can help bring your products to market faster, more reliably, and with unmatched quality.