The Future of Value-Added Manufacturing: How Advanced Technologies Are Revolutionizing the Industry

The field of electronics manufacturing is always changing, especially as new technologies are introduced that enhance or even replace older manufacturing methods. A big driving force in the development of these new technologies is the recent push for sustainability in manufacturing. New technologies, software, and value-added processes are developed in a way that helps contribute to reducing the environmental footprint of a manufacturing company.

Here are a few of the major advancements that have contributed to value added manufacturing practices.

These days, every type of manufacturing has incorporated IoT into their company in some way. The integration of IoT allows manufacturers to optimize and automate various manufacturing processes for improved quality and efficiency. Manufacturers like Cypress Technologies are taking advantage of smart devices and faster networks for predictive maintenance, supply chain optimization, and even reducing their carbon footprint. IoT can be used to manage energy consumption and find ways to reduce material waste, which contributes to a reduced environmental impact overall.

Artificial intelligence (AI) has proven especially helpful in many different types of manufacturing, especially when it comes to predictive maintenance and improved quality control. AI systems optimize maintenance schedules and reduce downtime through extensive analytics and machine-learning algorithms. Using these systems, manufacturers can more accurately and productively monitor their equipment in real time and determine when the machines are likely going to need maintenance. AI systems also allow manufacturers to enact much more accurate and consistent quality control measures, finding defects and anomalies that would otherwise be difficult to find with just a visual inspection.

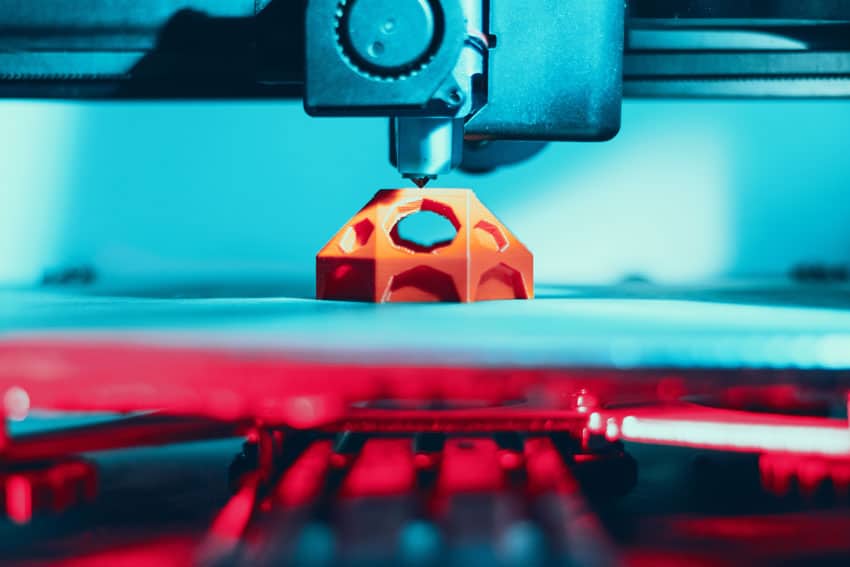

Additive manufacturing methods such as 3D printing have become more and more common in the electronics industry, especially for companies looking to reduce material waste. Additive manufacturing techniques have been applied to make many different types of electronic components, thanks to the flexibility in materials they can accommodate, including eco-friendly materials like recycled metals, and the versatility of shapes that these technologies can make. And these value added manufacturing methods produce little to no material waste, which makes them excellent choices for manufacturers and their customers who are looking to improve their sustainability.

Cypress Technologies is one such manufacturer that has been taking advantage of these advancements. We utilize an elite procurement system that manages prices for over 450 vendors around the world to ensure that we provide our customers with the most competitive costs. Lean manufacturing is how we do business and we implement Lean practices throughout our shop that ensure we provide excellent quality and improved sustainability. We ensure that material is only on our floor when necessary so that we can reduce our inventory, waste, and costs, and we have systems that ensure we can accommodate any design changes your product may need.

Interested in our services? Head over to our website to request a quote or contact us with any questions you may have!

Our People First Company Culture Fuels Success When you walk into Cypress Technologies, you will…

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

This website uses cookies.