Cypress Technologies’ lean operation improves quality and delivery by reducing cost and waste. In the next series of blogs I will address how Cypress Technologies’ operational direction and philosophy guides our organizational development. We borrowed the House of Lean from Pascal Dennis’, Lean Production Simplified, a great book. I have found no simpler tool to communicate the journey and sequence an organization must undertake to become lean.

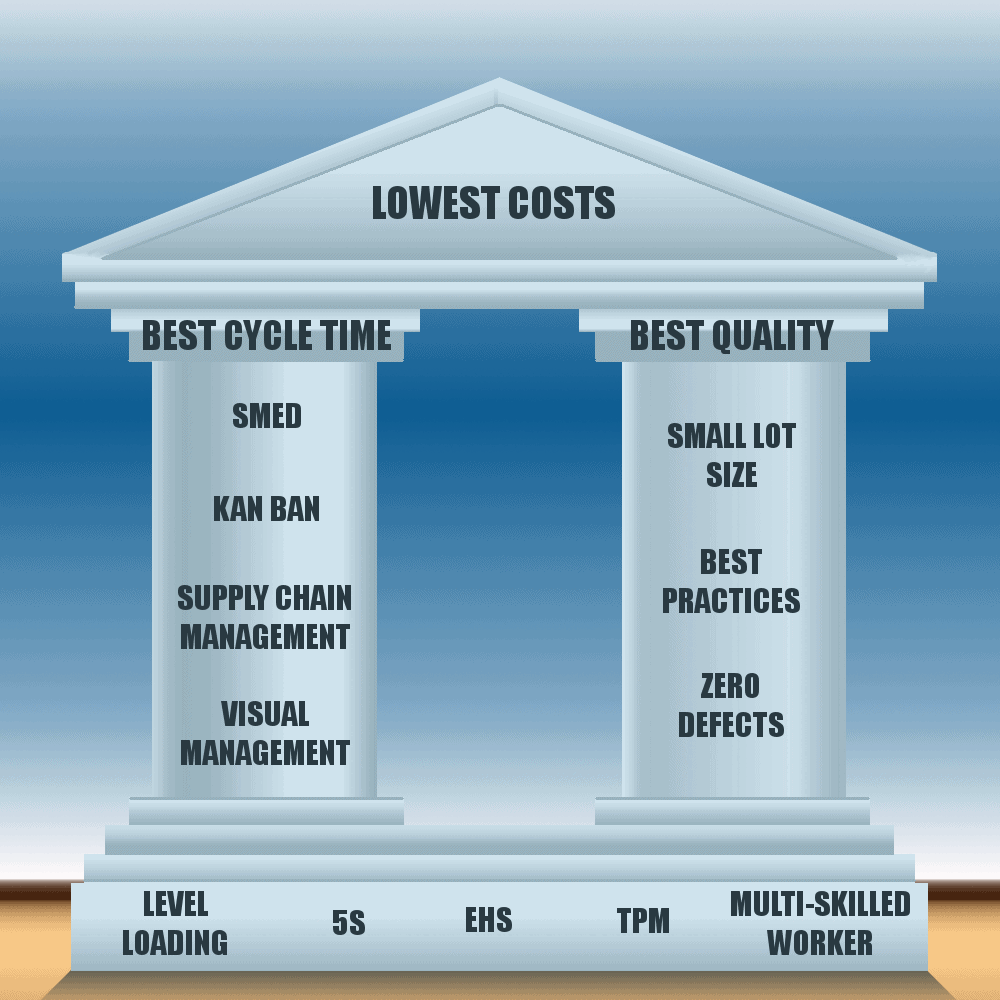

If one observes the House of Lean (HOL) as a whole, the picture above shows the HOL and the tools to build the house. These aren’t the only tools but they represent the most popular and relevant tools to most companies. The HOL has this assertion:

If an organization has the Best Cycle Time and Best Quality in its market, then, by rule, the organization will have the Lowest Costs.

Like all construction projects, it starts with a good foundation. Starting at the foundation of the HOL reside the tools that prepared the organization for the processes that people must master. These tools serve as basic training for the organization. I call these disciplines the “unsexy” side of Lean. These tools seldom take the spotlight, and are sometimes mistakenly assumed as a given, but each tool is critical to building an organization into thinking differently. The ideal outcome of mastering these tools is having people see the world with new perspective, identifying wastes not just at work but everywhere. Most importantly this builds the disciplines needed for more advanced tools later.

In today’s organization, 6S (sort, set in order, shine, standardize, sustain, PLUS safety) is the standard terminology used, but I still separate 5S and Environmental, Health, and Safety (EHS). However, no matter what one calls it, both are front and center in the HOL’s foundation. I do agree if an organization has created and mastered a world class EHS processes, 5S processes should be automatic. I also agree any company whose goal is to be considered world class must have a world class EHS program. It is imperative that management’s top leadership be involved in establishing EHS process norms. It’s natural for any organization to challenge change. Consistency by management will be the demonstrable proof that all will live by the new rules. EHS is also an excellent tool to start building teams. This has several advantages: first people start working together for a common goal, secondly, it quickly identifies individuals who can be leaders in the future, thirdly, and most importantly, a team approach to EHS allows better solutions to problems.

After the organization, has experienced the pains of establishing and managing teams, the next block in the foundation is Total Planned Maintenance (TPM) and Multi-Skilled Worker.

Let’s focus on TPM first. If production equipment is constantly breaking, lean manufacturing is an impossibility. It’s so important most companies start their lean efforts here. Therefore, the organization must ensure key production equipment is always ready to meet customer demand. This does not imply the equipment must be the newest or fastest. Some of the best equipment I’ve ever been around was World War II surplus, but it was so well maintained it always had excellent uptime. What does it imply? A lean organization constantly evaluates uptime and capacity to ensure the organization has the Ability-to-Promise (ATP) accurate delivery dates to the customer. This not only holds true for production equipment, but information systems as well. Cypress is no different, new equipment is being added to ensure more stringent quality and production demands are met.

The most crucial of all the foundation blocks is the Flexible Worker. All lean tools are built to do one thing, continuously improve the worker’s environment so they can effectively meet the Customer’s demand. The primary management tool that ensures this is the Flexibility Chart. It’s a simple tool that tracks the products and processes that each worker has mastered. It also identifies the training needs for each person in the organization. Obliviously the more products a worker can produce, the more value they add and should be rewarded for their knowledge and skills. It is management’s responsibility to ensure there is a path for motivated workers to achieve their goals. There will be more on this tool in later writings.

Finally, Level Loading is a powerful, but quiet block in the foundation. After the mastering of 5S, EHS, TPM, and Flexible Workers, Leveling Loading techniques are a critical technique of a Lean Organization. Level Loading of all work centers facilitates all lean tools that follow. Performed incorrectly, no tool will work and lean is impossible. The most common mistake is to assume level loading is building a bunch of the same “stuff”. Frankly it’s just the opposite. It’s optimizing the value-added resources in the organization. The ideal mix is a one-by-one production schedule, and Cypress is well on its way to developing tools and processes to achieve this vaunted goal.

-Brian Jenkins

General Manager

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

Once characterized by resource-heavy methods and significant waste, traditional manufacturing processes are evolving to embrace…

This website uses cookies.