Industrial EMS: What’s in a Name?

Exploring the differences between EMS, CEM, ODM, and OEM

If you work in the manufacturing field or have worked with any type of manufacturer in the past, you have probably come across one or more of the acronyms mentioned in the title. Each one refers to a type of manufacturer, and while they might perform similar functions–after all, each one to some extent manufactures a product–they are actually very different. Whether you’re new to manufacturing and are looking for a quick guide or you’ve been in the field a while and want a refresher, here are the major types of manufacturers.

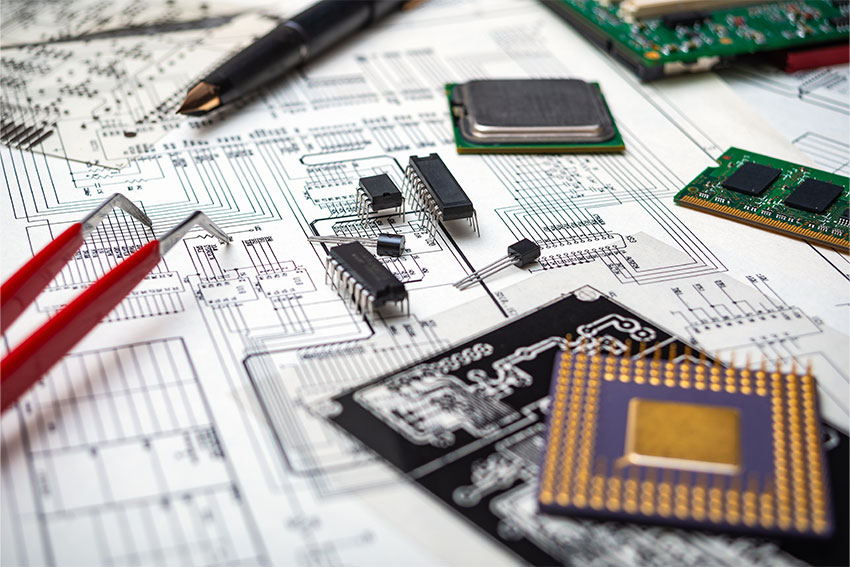

EMS is the unique one out of the acronyms, as it doesn’t refer to a company but a service that can be provided by all of the different types of companies that we’ll go over in this article. Providers of industrial EMS services like Cypress Technologies create an electronic component from its design all the way through manufacturing, testing, and distribution. They also repair the end-use products that these components are integrated into, and provide shipping management, procurement assistance, and important customer service.

A CEM is a manufacturer who specializes in PCB and electromechanical assemblies, typically supporting OEMs with more substantial products that are branded with the buyer’s logo. CEMs like Cypress are highly certified and experienced with regulations and industry standards, and also provide support for the products that they design, test, and sell to OEMs.

ODMs typically design and manufacture very specific products that other companies are looking to use in their products, or that they want to sell under a brand name. They’re in charge of all the product R&D and sometimes even sell their products on their own without going through a third party. This typically isn’t a customized product like what you can get from a CEM or OEM, but a product that the ODM has a proven track record for making.

OEMs are contract manufacturers, designing and producing a product based on buyer specifications, and the final product is sold under the buyer’s logo. OEMs typically don’t design products for their own sales, but according to the needs of their partners. OEMs come in all different types beyond just electronic manufacturers and can be found in any industry.

Cypress Technologies is a full-service CEM providing industrial EMS services for a wide range of partners. We have an expert engineering and design team, as well as several electronics manufacturing capabilities such as box and panel assemblies, PCB assemblies, electromechanical assemblies, testing and test fixture design, and much more. Check out our website to request a quote on your next project!

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

Once characterized by resource-heavy methods and significant waste, traditional manufacturing processes are evolving to embrace…

This website uses cookies.