Printed circuit boards or PCBs play a key role in most electronics. If you take apart any advanced device, you’re likely to see the small chip with its characteristic green color and copper lines. Because of how widespread they are, PCB assembly has become a common, but vital service of electronic contract manufacturers. In this article, we’ll go over the basics of the PCB assembly process, including the major components of a printed circuit board assembly and the steps involved in the process.

What is a PCB and what is a PCB assembly?

Printed circuit boards are small green chips made of fiberglass and copper (or another metal) lines that provide connections between the components on the board. The whole board is held together by an epoxy and insulated with a solder mask, which gives it the characteristic green color.

PCB assembly is the process of mounting small components onto the circuit board in order to ensure that it functions a certain way. Typically, PCBAs are used for more advanced applications or for electronics that will serve a very specific purpose. PCB assembly can be automated or manual, though these days, automated assembly is much more common thanks to advancements in robotics technology. However, there are still certain steps that are typically manual, especially depending on the type of PCB being crafted.

The typical parts of a printed circuit board assembly

The base of a PCB consists of several key components that are largely the same across all boards. The substrate, which can be rigid, flexible, or metal, is what gives the board its rigidity (or flexibility). Rigid substrates are the most common, typically consisting of fiberglass, but flexible boards like Kapton plastic are popular for applications that require more bendable and temperature resistant boards. Another alternative is the metal core PCB, which tends to spread heat more efficiently and protect components on the board that are more heat sensitive.

The next layer is the copper foil, which can adhere to either or both sides of the substrate. After the copper is added, a solder mask covers the entire board, keeps everything in place, and provides places of attachment for any components added. The final layer is a silkscreen, which typically consists of labels that indicate the function of each component on the board.

The technology of PCB assembly

There are two basic types of equipment used in PCB assembly processes. The main one is surface mount technology (SMT) which places sensitive and typically very small components such as resistors or diodes. This is almost always automated these days for more efficient and effective assembly.

The other basic type of equipment used in PCB assembly is Through-Hole Insertion Technology (THT), which is excellent for larger components with leads or wires that have to be plugged through holes. It’s usually used for components like capacitors and coils, and can be either manually done or automatic.

The basic steps of PCB Assembly

- Solder Paste Stencil

- The solder mask is applied to the PCB where the components will eventually sit. This paste is important for ensuring adherence on the finished board.

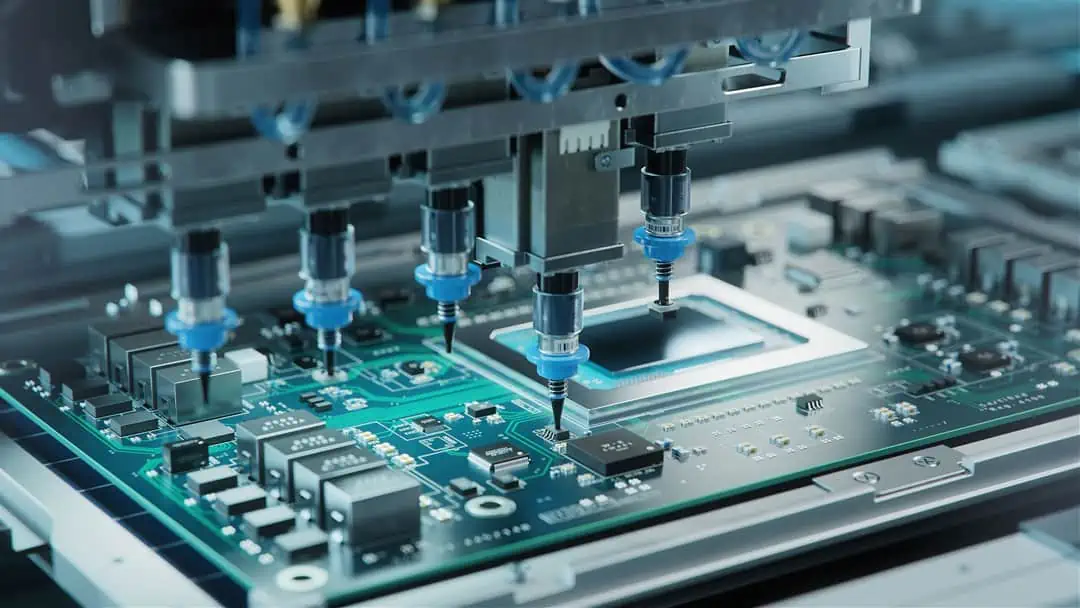

- Pick & Place

- Once the solder paste has been applied, the boards are sent on a conveyor belt to robotic pick and place equipment, which add surface mount components to the board.

- Reflow Soldering

- Once all of the surface mounted components have been added, the PCBs are transferred to a conveyor that takes them through a reflow oven to melt the solder. The boards are allowed to cool and solidify in a controlled environment after that to ensure that everything will remain in place.

- Inspection & Quality Control

- After the PCBs have cooled, they are tested for functionality. This step also ensures that there are no misplaced components or improper connections on the board.

- Through-Hole Insertion

- This step is not always necessary, depending on the components that need to be added to the board. Any plated through-hole components are added during this step, and specialized soldering is completed for them as well. The soldering can be manual or automated (which is also known as wave soldering).

- Final Inspection & Cleaning

- All final quality checks are completed, and any residue from the assembly process is cleaned off in preparation for the delivery of the finished PCBs.

Looking for a supplier of PCB assembly services?

Cypress Technologies has been providing proven, hassle-free electronic manufacturing services to our customers since 1987, offering everything from prototype to production. Check out our website to learn more about how we can take your electronics to the next level.