One of the most common practices in electronics manufacturing is the outsourcing of printed circuit board (PCB) assemblies to third party manufacturers. This service saves OEMs a great deal of time and money, as PCB assembly typically requires specialized equipment and experienced staff. By outsourcing the assembly, the OEM won’t need to invest in acquiring that equipment or hiring extra staff. Instead, the electronic contract manufacturer, who already has all of those resources in place, can perform the operations for them.

Outsourcing PCB assembly has many other benefits as well. Typically, electronic manufacturers have a supply chain in place that the OEM can take advantage of, getting better pricing for components and materials that might have cost extra otherwise. Also, the OEM doesn’t have to designate any manufacturing space in their own facility to install the equipment necessary for PCB assembly. The space that would have been needed can instead be used for their own operations.

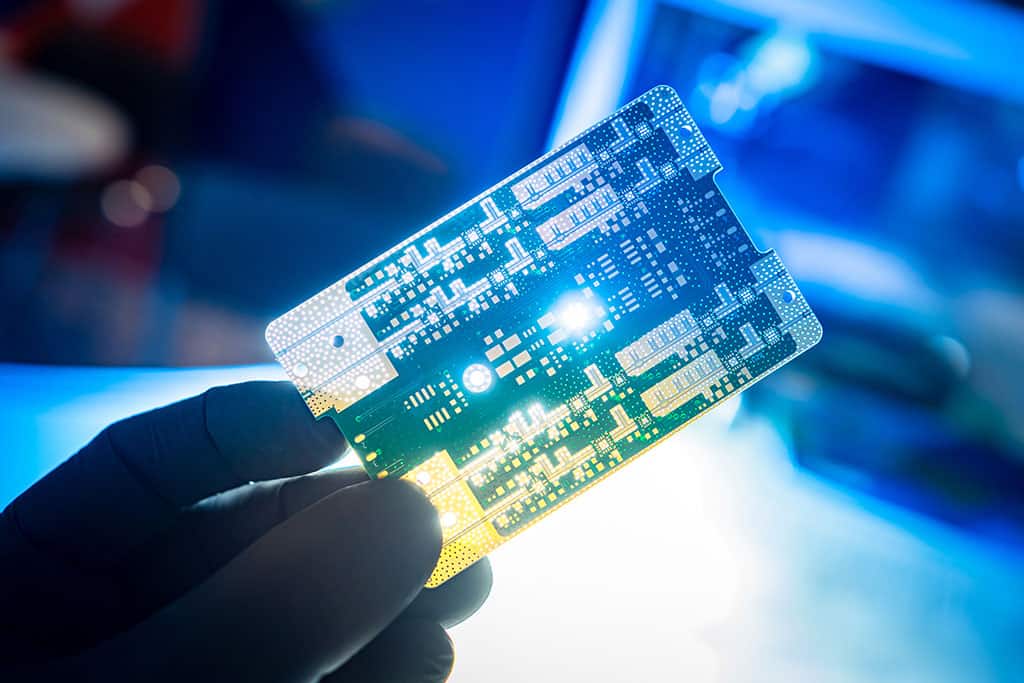

Another benefit of outsourcing PCB assembly is the ability to get a product with a much higher level of quality. Electronic manufacturers specialize in these types of services, and they have the experience to identify and correct potential issues in design or production, as well as the necessary equipment to produce PCBs efficiently. They will also be well versed in the quality standards that these components have to meet, and will have the capability to build them to those standards.

In addition, electronic contract manufacturers are set up to produce these assemblies with better efficiency compared to the OEM. They have the staff, the equipment, and the system in place to manufacture and assemble PCBs with quick turnaround times. Not only that, but they’ll have the experience necessary as well to monitor the production process and identify and correct issues if they arise.

Cypress Technologies has been a leader in PCBA and other electronics manufacturing services since 1987. We have a solid network of vendors that helps us provide a flexible approach to manufacturing, while keeping our prices competitive. For more information, check out our website.

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

Once characterized by resource-heavy methods and significant waste, traditional manufacturing processes are evolving to embrace…

This website uses cookies.