Box build assemblies are an integral part of custom electronics manufacturing. Rather than sourcing the various components of the assembly to different manufacturers–such as the PCBs, cables, and enclosure–everything is sourced, made, and assembled by one supplier. Typically, each part of box build manufacturing is customized specifically to meet customer requirements. That includes not just the various components of the assembly, but also the function as well, ensuring that the final product will be compatible with the customer’s existing systems and will ensure that those systems run as smoothly and efficiently as possible.

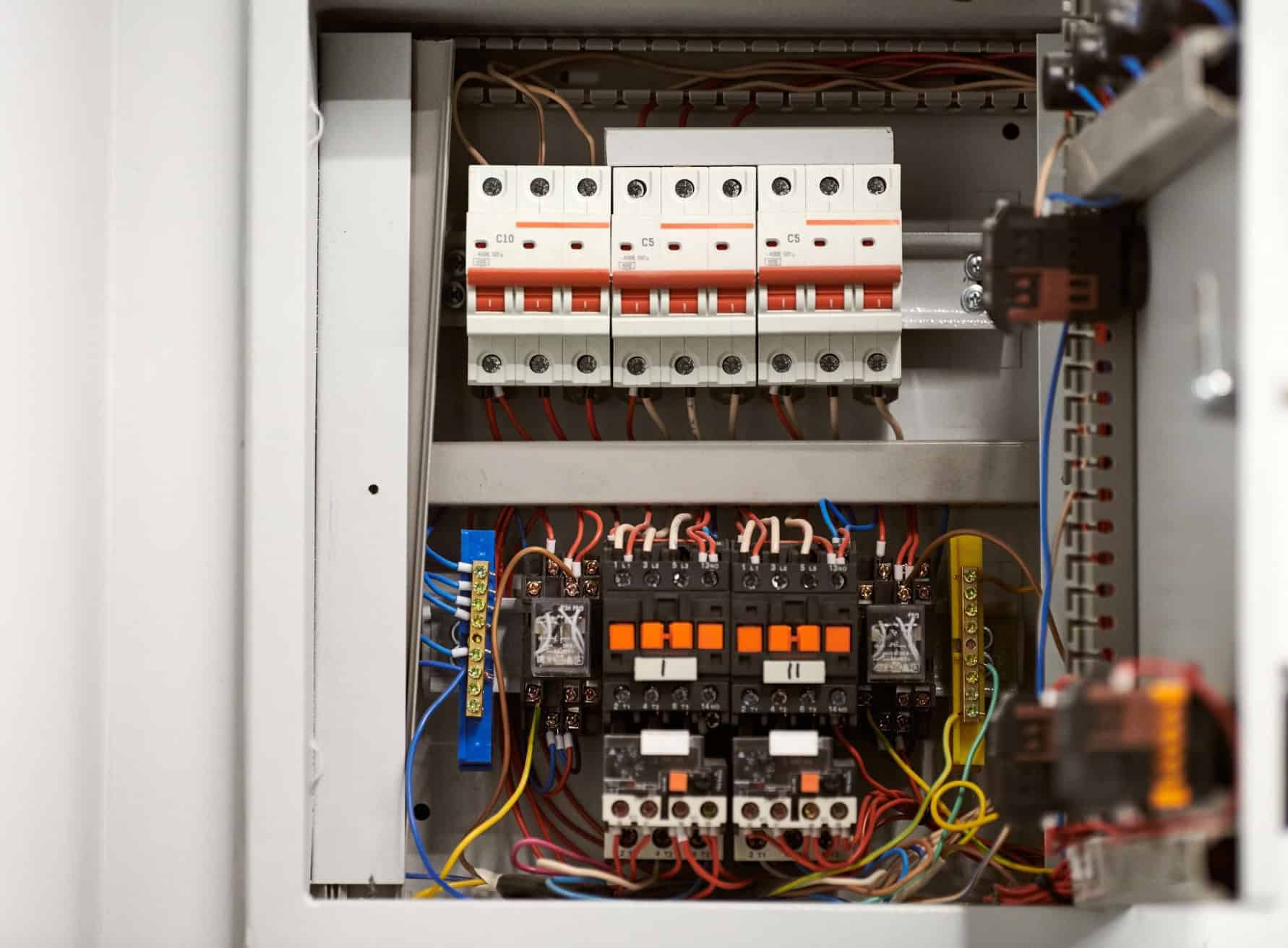

Cypress Technologies specializes in particularly complex or challenging box build assemblies, offering custom builds according to our customers’ needs. We offer what we call end-to-end solutions, providing everything from component sourcing to final assembly and testing, all under one roof. This allows us to provide a high quality and cost effective product that is specifically designed to meet the unique requirements of the customer.

Cypress offers expert solutions for high-value box build assemblies that are typically difficult to create and require extensive testing and inspections. We work closely with our customers throughout the entire process to ensure that we provide them with the best possible product for their needs.

Whether you have a fully-fledged design or you want assistance to develop a product concept, our experts offer their knowledge to conceptualize, design, and prototype the box build. The engineering team works closely with our manufacturing team to ensure the design will translate well into a physical prototype.

Cypress Technologies utilizes an elite procurement system that manages pricing for over fifteen hundred vendors around the world. We offer our customers extensive negotiating power on material availability, component features, and pricing, so that they can get the best possible value. Our system uses a combination of MRP, Lean, and JIT tools as well, in order to bridge the gap between what’s on paper and the actual market demand.

Cypress has one of the most experienced teams of electronics manufacturers in the country, with decades of combined experience in the industry that we can offer. We are a one-stop shop, accommodating PCB, Cable & Harness, and Electromechanical assemblies in addition to box builds. We also offer custom machining of metals and plastics in-house to ensure that whatever components that need to be included in the assembly are available.

In addition to manufacturing and assembling box builds for our customers, we also are highly experienced in testing and test fixture designs. We’ll perform a wide range of quality inspections such as troubleshooting, repairs, and failure analyses to ensure that the final product meets with customer requirements. In addition, we offer full program documentation for material traceability and data integrity.

Cypress Technologies has been offering proven electronics manufacturing solutions since 1987. Check out our website to request a quote or learn more.

The choices electronics manufacturers make when sourcing materials go far beyond cost and efficiency. Ethical…

The promise of new tariffs under the incoming administration creates challenges for companies reliant on…

The manufacturing industry is transforming as businesses increasingly focus on sustainability. Instead of sticking to…

In electronic manufacturing, quality is more than a feature—it’s the backbone of every successful product…

Reducing waste in manufacturing is not just a strategic choice; it’s an essential practice for…

Once characterized by resource-heavy methods and significant waste, traditional manufacturing processes are evolving to embrace…

This website uses cookies.