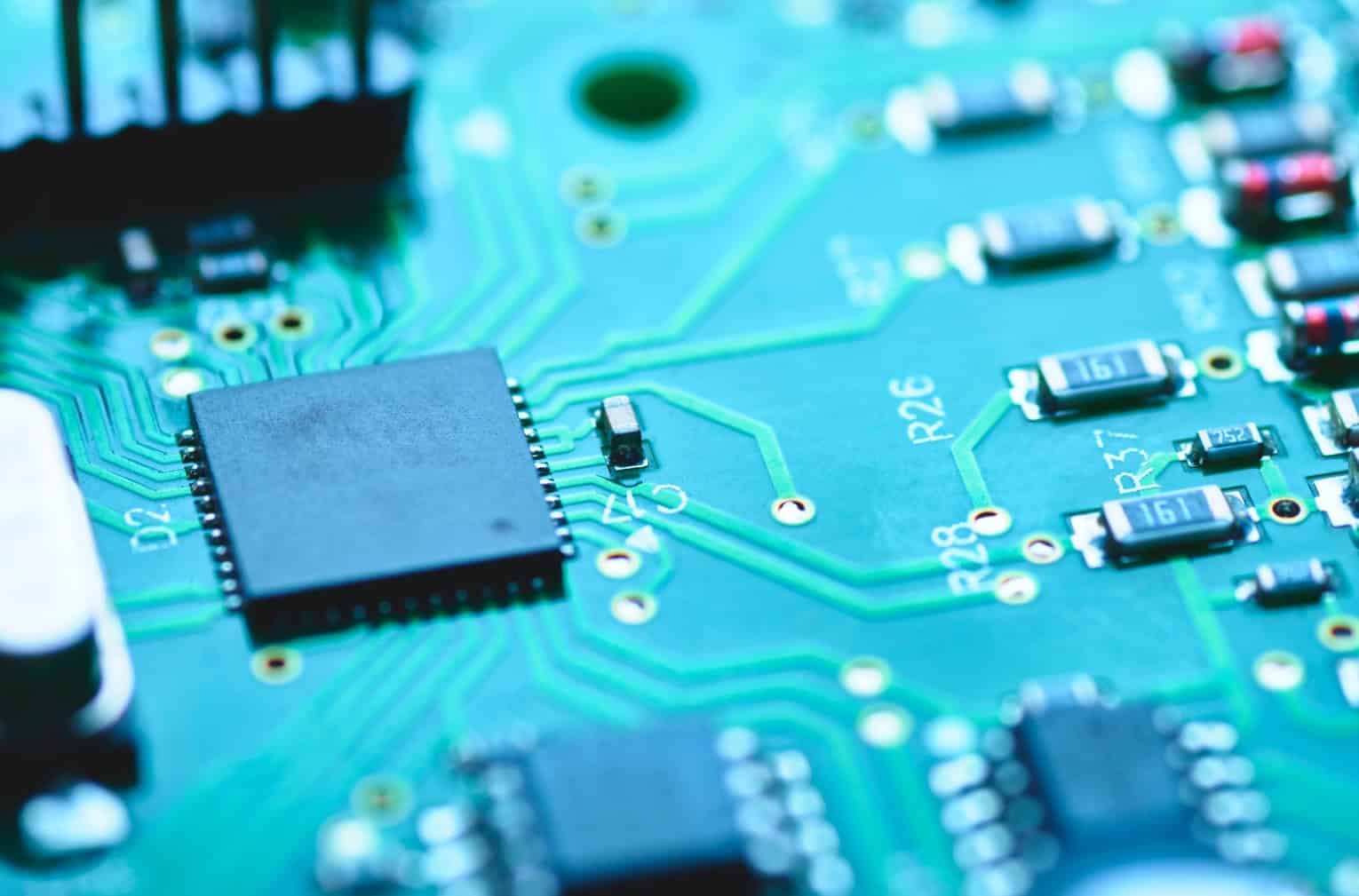

The printed circuit assembly (PCA) or printed circuit board assembly (PCBA) has long played a critical role in the creation and functionality of modern electronics, being the main building block for nearly every single modern device across the world. Without PCAs, technology would not have advanced nearly as fast or as far as it has.

How Printed Circuit Assemblies are made

PCAs are incredibly widespread, found in nearly every device–but the actual assembly of a printed circuit board and all of its components is an intricate task. Printed circuit boards or PCBs serve as the base for the assembly, consisting of a substrate typically consisting of fiberglass or specialized plastic, mounted with the necessary components, and then covered with epoxy and a solder mask for insulation and protection.

Components are typically added through surface mount technology (SMT) which uses automation to place sensitive and typically small components like resistors or diodes onto the board. For larger components with leads or wires that have to be plugged through holes, through-hole insertion technology (THT) is used, either manual or automatic.

Once everything has been assembled, the PCA is then tested for proper functionality and inspected for misplaced or missing components and improper connections. If you’re interested in learning more about how printed circuit board assemblies are made, check out our article on the basics!

PCAs–The Cornerstone of Modern Electronics

Printed circuit assemblies are found in just about every electronic device in every industry around the world. They connect the various components of the device together, allowing for communication between them and ultimately allowing the device to function. There are PCAs in smart phones and other smart devices, complex ones in computers and related technology, even in consumer products like refrigerators and microwave ovens.

More durable PCAs can be found in the engines of aerospace equipment and under the hood of your car, where they are exposed to oil, heat, water, and vibration. They provide critical functionality to braking systems, flight control operations in environments where electronics typically would not function properly. They’re vital in the healthcare industry, allowing for the development of life-changing and even life-saving technologies. These days, more often than not, nearly any electronic device has some sort of PCA built into it, whether simple or complex, for smoother operation and more efficient functionality.

Cypress Technologies–Helping Our Partners Push the Boundaries of PCAs

Cypress Technologies has been an electronic manufacturer since the 80s, and we’ve seen firsthand how quickly the marketplace can change and how fast technology has advanced. We are a full-service contract manufacturer for the electronics industry, providing engineering and design services as well as a wide range of box build manufacturing, PCB assembly, electromechanical and harness assemblies, and much more.

Are you looking for an expert electronics contract manufacturer? Consider working with us! We are dedicated to our customers, leveraging a large procurement system and our extensive industry experience to provide them with solutions tailored to their needs. Check out our website to contact us or learn more!